MONOLITHIC

ISOLATION JOINT

GENERAL

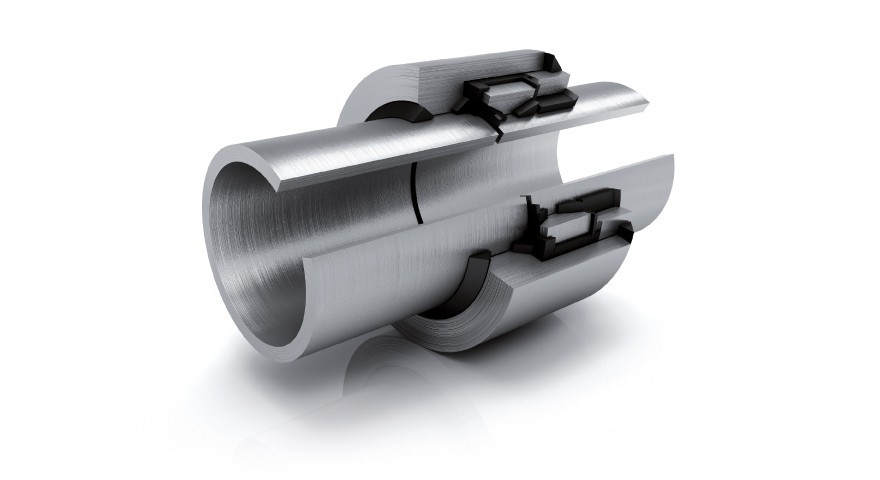

A Monolithic Isolation Joint (MIJ) is a specialized component used in pipelines to provide electrical isolation

between different sections of the pipeline. The Purpose of the isolation joint is to prevent detrimental electro-chemical

interaction and improve the effectiveness of the cathodic protection system. Isolating joints are also used to ensure effective

current distribution for cathodic protection system.

FUNCTIONAL REQUIREMENTS

-

Isolation joint shall be suitable for Pigging Operation.

-

Slip-on Flanges shall not be used.

-

The isolation joints shall be able to withstand the operating conditions

stated in the requisition sheets.

-

Where the operating conditions are not stated, the following operating conditions shall apply.

-

Installation: Above ground

-

Design temperature: 0°C ~ +90°C

FEATURES

-

Chemical resistance: Some MIJ are made of materials that are resistant to

chemical corrosion, which makes them suitable for use in chemical processing plants or other environments where chemicals

are present.

-

Wide temperature range: MIJ are designed to withstand a wide range of

temperatures, making them suitable for use in a variety of applications.

-

Easy to install: MIJ are easy to install, as they do not require

any special tools or equipment.

-

Non-conductive material: The primary feature of MIJ is that it is made of a

non-conductive material, which prevents the transfer of electrical current.