ALUMINIUM

ANODE

GENERAL

Aluminium alloyed with traces

of Mercury, Zinc and Silicon produces and anode with a capacity over three

times that of zinc and a driving potential of 250mV against the protected

structure. Therefore Aluminium anodes are commonly used in saltwater or offshore

environment due to their relatively low consumption rate of approximately 7 lbs

per amp-year.

TYPICAL APPLICATIONS

In saltwater environments

where electrical resistivities are usually quite low, Aluminium anodes are the

most economical choice for corrosion protection. These anodes offer higher

current efficiency and lower anode consumption than both magnesium and zinc in

aqueous saline areas.

Galvalum I has an open circuit

potential of 1.05 V (vs Ag/AgCl reference cell), contain a nominal amount of

mercury

and is recommended for use only in free flowing saltwater environment.

Galvalum III has an open

circuit potential of 1.10 V (vs Ag/AgCl reference cell), produces a higher

ampacity and better performance in higher temperature environment, lower

chloride

water and saline mud electrolytes.

CHEMICAL COMPOSITION

|

Element |

Normal

(%) |

|

Zinc |

2.5 - 7.5 |

|

Indium |

0.015 - 0.040 |

|

Cadmium |

≤0.002 |

|

Silicon |

≤0.12 |

|

Iron |

≤0.09 |

|

Copper |

≤0.003 |

|

Aluminium |

Remainder |

Chemical composition based on

DNV Standard. Other compositions are also available upon request.

Electrochemical Capacity :

2540 to 2730 Amp.hr/Kg (ambient temperature)

Closed Circuit Potential :

-1.05V (seawater) w.r.t Ag/AgCl Reference Electrode

AVAILABLE TYPES OF ALUMINIUM ANODES

Aluminium anodes can be casted

into various shapes such as:

1.

Stand-off Flat Bar Core

2.

Stand-off Cylindrical Core

3.

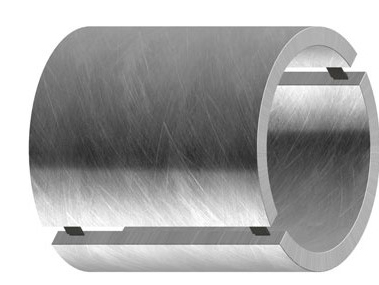

Cylindrical Bracelet Anode

4.

Tapered Bracelet Anode

5.

Weld-on Type / Bolt-on Type Hull Anode

Stand-Off Flat Bar Core Anode

Bracelet Anode

Order Information

Shapes and sizes of anodes can

be specified upon order to meet customer's requirement.

Specify the following details

upon ordering:

1.

Anode Quantity

2.

Anode Shape/ Type

3.

Anode Weight

4.

Anode Dimension

5.

Chemical Composition (If required)