REMOTE

MONITORING SYSTEM

GENERAL

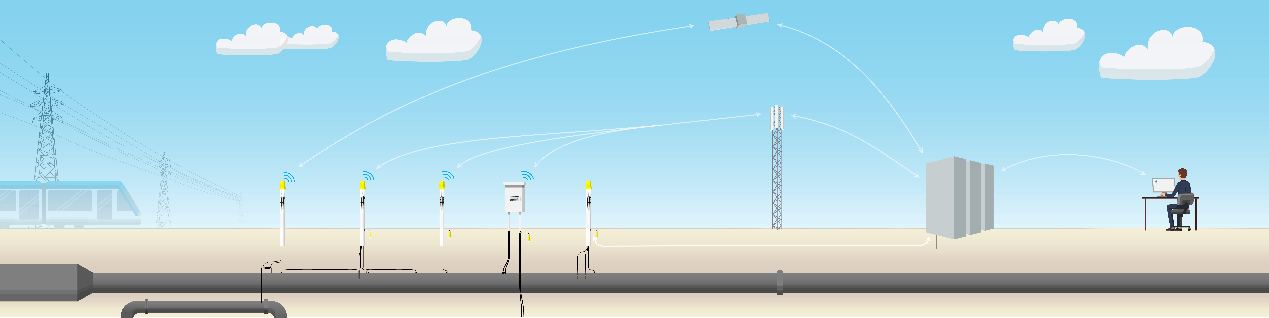

Remote monitoring of a Transformer Rectifier in an Impressed Current Cathodic

Protection (ICCP) system involves using advanced technology to carefully watch and control the rectifier's performance from a

distance. In the ICCP system, the rectifier generates electric current to protect metal structures from corrosion. Inside the

rectifier, sensors collect important data like current, voltage, and temperature. This data is continuously gathered and processed

by the rectifier's control system. The rectifier connects to a communication network, like cellular networks, Wi-Fi, or Ethernet,

allowing data to travel across the network to a central monitoring location. Authorized personnel access the rectifier's data remotely

through a secure online platform, using computers, smartphones, or dedicated monitoring devices.

FUNCTIONS OF THE SYSTEM

-

Logging in to user management

-

Testing pile alarms and sampling settings

-

Data browsing and curve drawing

-

Data export

USAGE OF THE SYSTEM

1.

The system is logging in by entering the domain name and IP address in the browser (Google Chrome) to displace the

login page, then the name, password, and verification code entered on the website of the system.

2.

The system is set up by adding and deleting test station equipment.

3.

Data is browsing and exporting by clicking the test station icon shown

on the page to view the current test station data.

4.

Management domains of test stations must establish alarm rules to remind users of maintenance and ensure the system

functions correctly. The bell icon will shake to alert users about abnormal operation data in the system.